Whole House Stone Customized Equipment

Whole House Stone Customized Equipment

Service Hotline

008618560129901

Whole House Stone Customized Equipment

Whole House Stone Customized Equipment

008618560129901

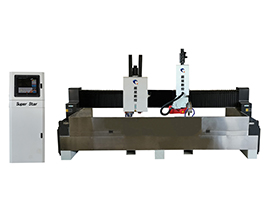

Performance characteristics:

This machine has the functions of digging basin hole, cutting straight edge and irregular Roman edge and polishing them. A hole digging machine head with high-power edge grinding motor can easily solve the problems of hand shaking cutting and hole digging, and uneven quality of processed products. It also expands the functions of special-shaped processing such as lettering, relief, hollowing, chamfering, line carving, etc. The machine performance is stable, the special quartz stone cutting system, directly modify the number can automatically generate the processing path, without the foundation can also quickly start to operate. The machine is environmentally safe and cost-effective. On the basis of this function, a saw blade head is added separately, which greatly improves the cutting speed and efficiency. The saw blade can be adjusted by 0-90 degrees, suitable for 45 degrees of undercutting, and can turn 90 degrees left and right, and the longitudinal cutting is completed horizontally.

Technical parameters:

Model | CXSC3015Table processing center |

Working area | 3000mm*1500mm |

Lathe bed | Seamless welding of thick wall square steel |

Nose | 320mm wide (cast iron) |

beam | 200mm*300mm*10mm |

Side panel | Steel side plate (carbon steel) |

mesa | Vacuum sucker |

principal axis | 5.5kW water-cooled spindle / 5.5kw/bt40 edging motor |

Spindle connection mode | Integrated electric spindle |

transmission | Taiwan 25 / 30 square rail, Xinyue 1.25m rack |

Blade Diameter | 350mm |

control | 70nc quartz cutting system |

Electric machinery | Servo motor 1.3kw/z axis 1.3KW + brake |

drive | Servo drive / reducer |

Carving instruction | G-code/HP-GL |

Material fixation mode | Vacuum sucker |

Vacuum pump | 5.5kW water circulation vacuum pump |

Cabinet | Vertical cabinet |

Spindle speed | 0-24000 (RPM) |

Power Supply | 380V/50HZ |

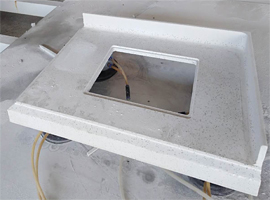

Sample Display

Online Message