Whole House Stone Customized Equipment

Whole House Stone Customized Equipment

Service Hotline

008618560129901

Whole House Stone Customized Equipment

Whole House Stone Customized Equipment

008618560129901

Characteristics

Fully automatic tool changer and various modeling grinding wheels, excavation, engraving, chamfering, polishing, European style edging for artificial stone, quartz stone, wash basin and tea tray of high-grade platen, kitchen cabinet panel, saving time and reducing waste , can improve the use of plates.

System: The automatic tool change system enables a high degree of automation from opening, cutting, to edge milling and polishing.

Tools: imported tools and abrasive tools, as well as various processing requirements.

High precision screw and guide rail: provided by Germany, the X, Y axis adopts the original oil-immersed lubrication method. The waterproof and dustproof structure ensures high precision of processing and maximizes service life.

Parameters:

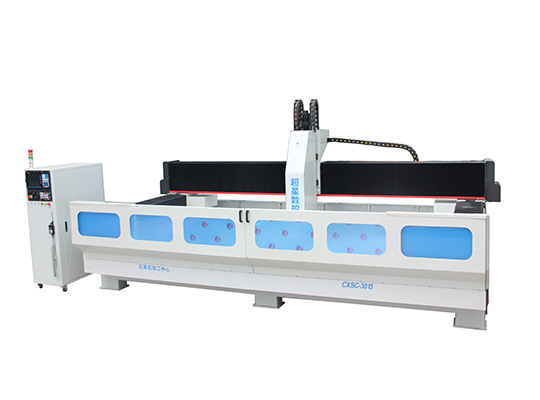

Model | Cxsc3015 automatic quartz processing center |

Lathe bed | 300mm * 200mm * 6mm Square pipe welding |

Nose | 320mm wide (cast iron) |

beam | 300 mm * 400 mm * 10 mm square pipe welding |

Side panel | Steel side plate (carbon steel) |

mesa | Aluminum alloy plate + vacuum suction cup |

principal axis | Taiwan 5.5kW servo mechanical spindle |

Spindle connection mode | Synchronous belt drive |

transmission | Taiwan 30 square rail, Xinyue 2.0m rack |

control | Weihong NK300 |

Electric machinery | Yaskawa servo plus brake |

drive | Yaskawa servo + Xinbao planetary reducer |

Tool magazine | 18 straight row magazine

|

Carving instruction | G-code/HP-GL |

Material fixing method | Vacuum sucker |

Vacuum pump

| 5.5kW water circulation vacuum pump |

Cabinet | Vertical cabinet |

Spindle speed | 0-8000 (RPM) |

Power Supply | 380V/50HZ |

Sample Display

Online Message