Whole House Stone Customized Equipment

Whole House Stone Customized Equipment

Service Hotline

008618560129901

Whole House Stone Customized Equipment

Whole House Stone Customized Equipment

008618560129901

Performance characteristics:

1. Adopt large section imported linear guide rail, free of maintenance and self lubrication for life;

2. Use BT40 to clamp the electric spindle of the large cutter, with the maximum rotation speed of the spindle reaching 12000rpm.

3. The worktable of the whole EPC has undergone strict annealing and other heat treatment processes to ensure the structural stability and rigidity of the bed.

4. Taiwan's new generation system is safe and reliable in operation, efficient in reading code, and has online simulation function and online monitoring function to ensure efficient and safe processing.

This product is mainly applicable to:

Foundry wood mold and foam model machining for large machine tools, ship heavy industries, etc.

1. Ship, wind power, machine tool, injection molding machine, printing machine and other mechanical casting wood models.

2. Industrial design of automobile, yacht, aircraft, etc.

3. Rolling mold, injection mold, GRG / GRC external wall decoration material processing, etc.

基本参数:

performance index | Model | 2550 |

Trip | X stroke | 2500mm |

Y stroke | 5000mm | |

Z stroke | 1000mm | |

Table size | 2500*5000mm | |

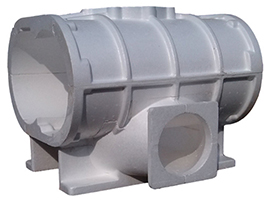

structure | Mesa structure | HT250 integral casting (optional T-groove steel plate) |

X, y, Z structure | X, Y-axis rack, z-axis lead screw | |

speed | Air speed | 16000mm/min |

Working speed | 12000mm/min | |

principal axis | Spindle power | Water cooled 7.5KW |

Spindle speed | 12000r/min | |

Inner taper hole of main shaft | Iso40 (maximum clamping tool diameter ¢ 32mm) |

Sample Display

Online Message